Yes, Three-Phase Induction Motors Are Self-Starting: Understanding the Why and How

Have you ever wondered what makes the big machines in factories, on farms, and in buildings just spring to life? The answer is often a powerful motor. But not all motors are the same. Some need a little help to get going, while others are ready to run the moment you flip a switch. This article answers a big question: is a three-phase induction motor self-starting? The short answer is a big YES! Read on to find out the simple magic behind how they work, why they are the workhorse of our world, and how we make them even better.

Table of Contents

- What’s the Big Deal About Starting a Motor Anyway?

- So, Is a Three-Phase Induction Motor Really Self-Starting?

- How Does This Magic Trick Work? The Rotating Magnetic Field

- What Makes the Rotor Spin? A Gentle Push from Science

- Why Doesn’t the Rotor Ever Catch Up?

- What About Single-Phase Motors? Are They Self-Starting Too?

- If It Starts Itself, Why Do We Ever Need Motor Starters?

- What Kinds of Starters Help These Motors?

- What Makes a Three-Phase Motor So Great for Big Jobs?

- How Does the Motor’s Build Help It Start and Run Well?

What’s the Big Deal About Starting a Motor Anyway?

Have you ever tried to push something really heavy, like a car? That first push is the hardest part. You have to lean in and use all your strength just to get it to move a little bit. Once it’s rolling, it’s much easier to keep it going. Electric motors are a lot like that. That first moment of getting started, called the breakaway torque, requires a huge amount of energy.

This can cause a problem. When a big motor starts, it draws a giant gulp of electricity from the wall. This is called the motor starting current or locked rotor current (LRC). Have you ever noticed the lights in your house flicker when the air conditioner or a big appliance turns on? That’s the same idea! The motor is pulling so much power that it causes a small dip, or “sag,” in the electricity for everything else.

Now, imagine a giant motor in a factory. When it starts, it can cause more than just a flicker. It can cause real problems for other sensitive equipment. A rough start can also be like a big jolt to the machine the motor is running. It can shake belts, gears, and bearings, causing them to wear out much faster. Finding a motor that starts smoothly and powerfully is a huge challenge for engineers.

So, Is a Three-Phase Induction Motor Really Self-Starting?

Yes, absolutely! This is the main reason why the three-phase induction motor is the king of the industrial world. You don’t need any fancy tricks or extra parts on the motor itself to get it to spin. When you connect it to a three-phase power supply, it just starts. This is called the self-starting property of induction motor.

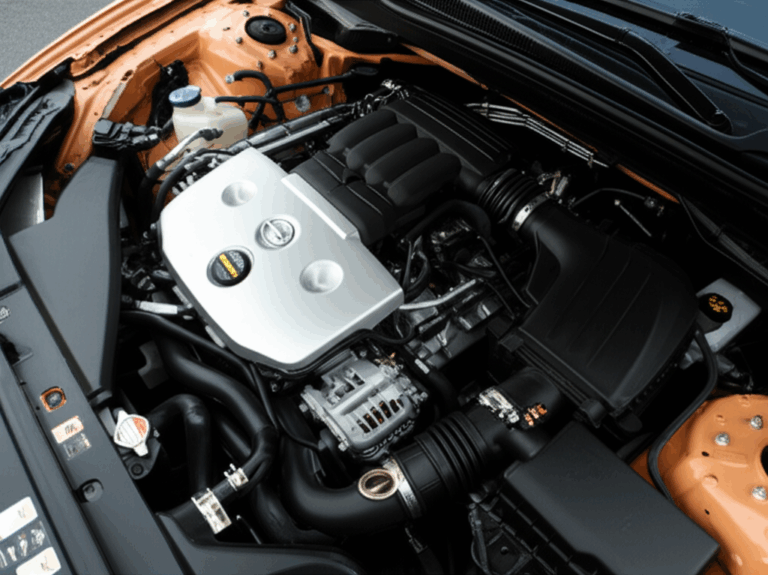

This makes it incredibly simple and reliable. Think of it like a car that starts perfectly every single time you turn the key, with no sputtering or hesitation. This dependability is why over 90% of motors used in industrial applications are three-phase induction motors.

This self-starting ability comes from a wonderful bit of science. It’s not magic, but it sure feels like it. The secret lies in the way three-phase power and the motor’s design work together to create a spinning force right from the start.

How Does This Magic Trick Work? The Rotating Magnetic Field

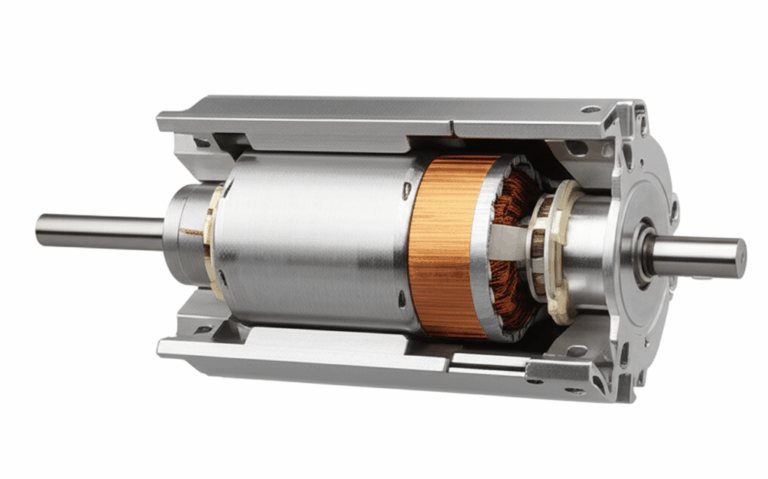

To understand how the motor starts itself, you need to know about its two main parts. The outside part that stays still is called the stator. The inside part that spins is called the rotor. The real magic happens in the stator. The stator has wires, called motor windings, wrapped around it in a special way.

When we connect a three-phase power supply, it sends three waves of electricity to these windings. These waves are perfectly out of sync with each other, each one peaking at a different moment. Imagine three people tossing a ball around in a circle, one after the other. This flow of electricity creates a magnetic field. But because the power comes in three separate, timed waves, it creates a rotating magnetic field (RMF).

It’s like an invisible hand is spinning a giant magnet inside the stator. This magnetic field rotates at a constant speed, known as synchronous speed. This spinning field is the key. It’s the force that will get the rotor to move, all without touching it. It’s a core part of the motor principle that powers our world.

What Makes the Rotor Spin? A Gentle Push from Science

Now we have this invisible spinning magnetic field in the stator. But what about the rotor? The most common type of rotor is a squirrel cage rotor. It looks a bit like a hamster wheel and is made of solid bars of metal connected at the ends. These bars are great conductors of electricity.

Here’s where two famous laws of science come into play. First is Faraday’s Law of Induction. This law says that if you move a wire through a magnetic field, you create electricity in that wire. In our motor, the magnetic field is moving past the stationary rotor bars. So, the spinning magnetic field from the stator creates, or “induces,” an electric current in the rotor’s bars.

Next comes Lenz’s Law. This is a fun one. It says that the current you just created will make its own magnetic field. And this new magnetic field will try to oppose the change that created it. The change was the stator’s field spinning past the rotor. To stop this change, the rotor’s magnetic field will try to “catch up” to the stator’s field. The two magnetic fields—one from the stator and one from the rotor—push and pull on each other. This creates a force, or torque, that makes the rotor spin!

Why Doesn’t the Rotor Ever Catch Up?

So the rotor is chasing the rotating magnetic field. But here’s a funny secret: it can never, ever catch up. If the rotor did reach the same speed as the magnetic field (synchronous speed), then from the rotor’s point of view, the magnetic field would no longer be moving past it.

Think about driving on the highway. If you are going the same speed as the car next to you, it looks like that car is standing still. If the rotor caught up, the magnetic field would look like it was standing still. According to Faraday’s Law, if there’s no changing magnetic field, there’s no induced current in the rotor. No current means no rotor magnetic field, and no magnetic field means no torque. The rotor would stop getting a push!

So, the rotor always has to spin a little bit slower than the magnetic field. This difference in speed is called slip. It is this very slip that allows the motor to work. The slip ensures that the magnetic field is always cutting across the rotor bars, inducing current, and producing the torque that keeps the motor turning and doing useful work, like running a fan or a pump.

What About Single-Phase Motors? Are They Self-Starting Too?

This is a great question, and the answer helps show why three-phase motors are so special. A single-phase induction motor, the kind you find in many home appliances, is not self-starting.

A single-phase power supply has only one wave of electricity. When it goes into a motor, it creates a magnetic field that just pulses back and forth. It grows stronger, then weaker, then reverses direction. It doesn’t rotate. Imagine trying to spin a merry-go-round by just pushing in and pulling out on one spot. It would just wiggle back and forth; it would never start spinning.

To get a single-phase motor started, it needs an extra trick. This is usually done with an auxiliary winding and a device like a capacitor. These parts help create a second, out-of-sync magnetic field for a moment. This gives the rotor that first little nudge it needs to start spinning in the right direction. Once it’s going, it can keep running on the single pulsing field.

If It Starts Itself, Why Do We Ever Need Motor Starters?

This seems like a puzzle, right? If the motor starts all by itself, why do we use extra equipment called motor starters? The answer goes back to that first problem we talked about: the huge rush of starting current.

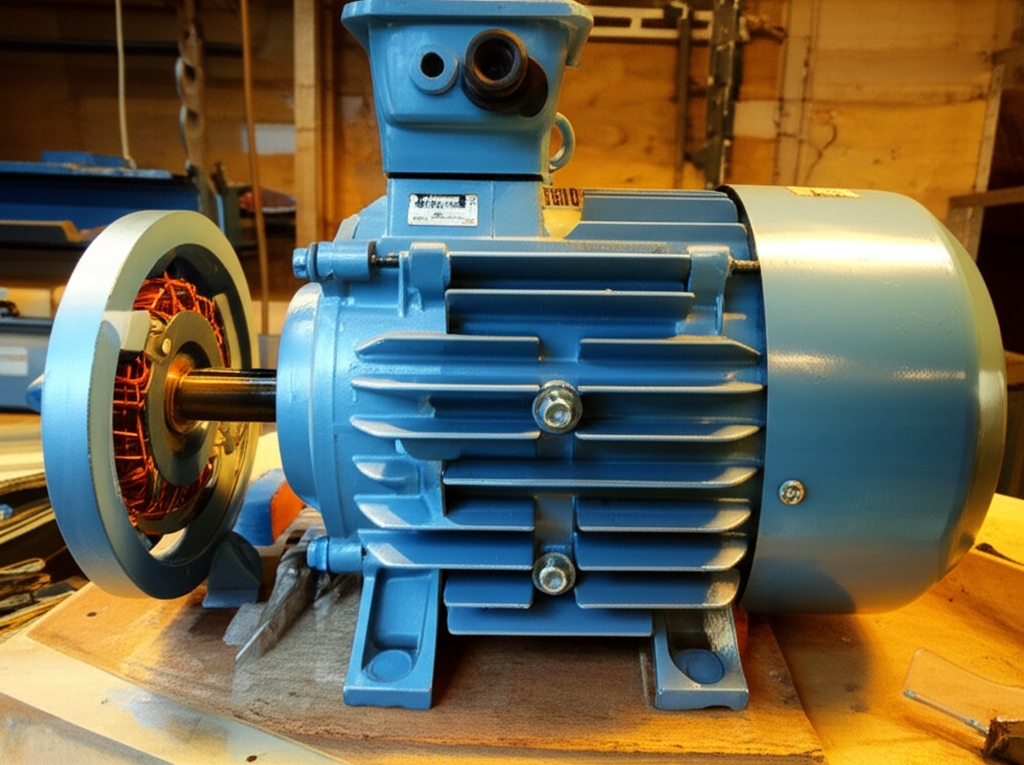

While a three-phase motor can start by connecting it directly to the power line (this is called direct online starting or DOL), it’s not always a good idea, especially for big motors. The starting current can be 5 to 7 times the normal running current! This can cause those voltage sags we talked about, and it can put a huge mechanical shock on the equipment.

So, we use motor starters not to start the motor, but to start it gently. They are like a ramp instead of a cliff. They help control the power going to the motor at the beginning. This reduces the huge inrush of current and allows the motor to speed up smoothly. This protects the motor, the machinery it’s connected to, and the whole electrical system.

| Starting Method | How It Works | Starting Current | Starting Torque | Best For |

|---|---|---|---|---|

| Direct-On-Line (DOL) | Connects motor directly to full power. | Very High (100%) | High (100%) | Small motors where current rush isn’t an issue. |

| Star-Delta Starter | Starts with lower voltage, then switches to full. | Reduced (~33%) | Reduced (~33%) | Medium motors with light starting loads. |

| Soft Starter | Uses electronics to slowly ramp up the voltage. | Adjustable | Adjustable | Large motors needing a very smooth start. |

| VFD (Drive) | Controls both voltage and frequency. | Fully Controlled | Fully Controlled | Applications needing speed control. |

What Kinds of Starters Help These Motors?

There are a few common ways we give these motors a gentle start. A star-delta starter is a classic method. It connects the motor windings in a special “star” pattern to start, which lowers the voltage, and then switches them to a “delta” pattern for full power once the motor is up to speed. It’s a clever electrical trick.

A more modern solution is a soft starter. This is an electronic device that acts like a dimmer switch for the motor. It slowly increases the voltage from zero to full, giving the motor a perfectly smooth and controlled start. This is great for protecting delicate machinery like pumps and conveyor belts.

The most advanced option is a Variable Frequency Drive (VFD). A VFD gives you total control. It can change both the voltage and the frequency of the electricity going to the motor. This means you can start it as gently as you want, run it at any speed you want, and stop it smoothly too. VFDs are amazing for saving energy and getting precise control over a machine.

What Makes a Three-Phase Motor So Great for Big Jobs?

The self-starting ability is a huge advantage, but it’s not the only one. Three-phase induction motors are loved by engineers for many reasons. They have a simple and tough construction, especially the squirrel cage type. There are no brushes or parts that wear out easily, which means they need very little maintenance.

They are also very efficient. They do a great job of turning electrical power into mechanical power without wasting a lot of energy as heat. This is important for big factories where electricity bills can be huge. Their power output is smooth and constant, unlike the pulsing power of a single-phase motor, which makes them better for running heavy machinery.

Because they are so simple and reliable, they last a very long time. Many of these motors run for decades in tough conditions, covered in dust or working in hot factories, and they just keep going. They are the true unsung heroes of the modern world.

How Does the Motor’s Build Help It Start and Run Well?

The clever design of a motor is key to its power and long life. The stator and rotor are not solid chunks of metal. They are made of very thin sheets of special electrical steel that are stacked together. The quality of these sheets, known as motor core laminations, is incredibly important. At SinoLami, we specialize in making these high-quality laminations.

Using thin, insulated sheets instead of a solid block helps to reduce wasted energy. When the magnetic field is spinning, it can create little swirling currents of electricity inside the metal core, called eddy currents. These currents do no useful work; they just create heat. By using laminated sheets, we block these currents from flowing, which makes the motor much more efficient.

The quality of the stator core lamination ensures the magnetic field is strong and focused. Likewise, a well-made rotor core lamination helps the rotor respond perfectly to that field, giving you a powerful and efficient motor. It’s this attention to detail in the core components that separates a great motor from an average one.

Key Takeaways to Remember

Here’s a quick summary of the most important points:

- Yes, they are self-starting: Three-phase induction motors start on their own without needing extra parts, thanks to the rotating magnetic field created by three-phase power.

- Rotating Magnetic Field is the Key: The three waves of AC power create a spinning magnetic field in the stator, which is the “invisible hand” that starts the motor.

- Science Makes it Spin: Faraday’s Law and Lenz’s Law work together. The stator’s field induces a current in the rotor, which creates its own field, causing the rotor to spin as it “chases” the stator’s field.

- They are Different from Single-Phase Motors: Single-phase motors are not self-starting and need extra components like capacitors to get them going.

- Starters Are for Control, Not Starting: Even though they are self-starting, we often use starters (like DOL, Star-Delta, or Soft Starters) to control the high starting current and provide a smooth, gentle start.

- They are the Workhorse of Industry: Their simple design, high reliability, efficiency, and self-starting nature make them the top choice for almost every industrial job.